Honing process to improve the surface roughness of helical gears

Publication time: 2020-03-27 Website: https://ptogearboxes.com Edit: EP

In the process of manufacturing, due to the existence of machine tool errors, tool installation errors and other factors, thegearThe geometric dimensions of each part cannot fully meet the requirements of the design standard, which affects its manufacturing accuracy.The size of the tooth surface roughness has a direct effect on the wear, strength, energy consumption, life, rust and stability of the gear pair.

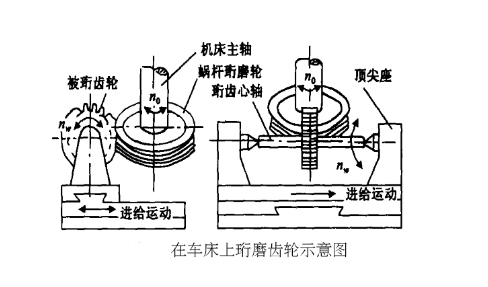

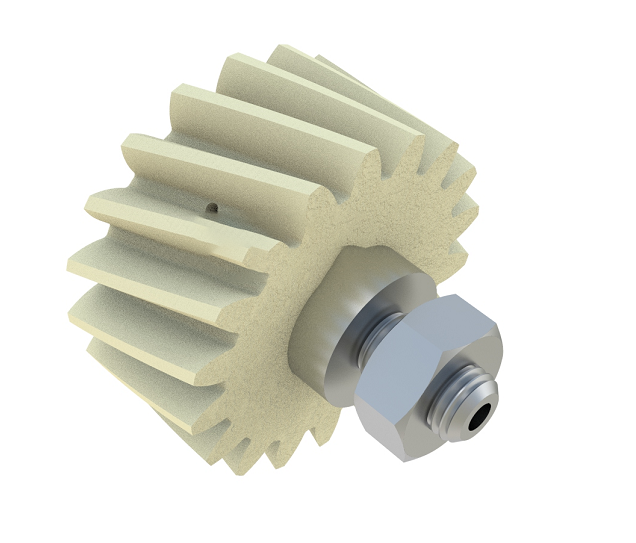

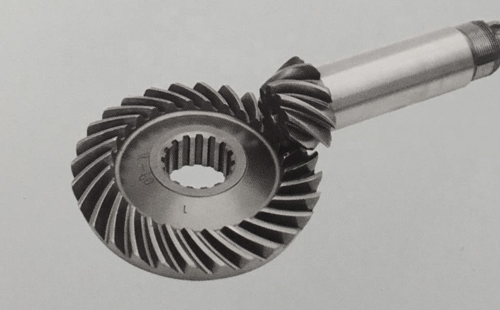

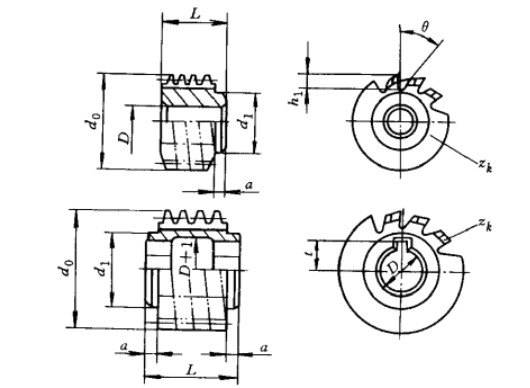

In order to improve gear meshing accuracy and surface quality, during milling, the length of the common normal line should be left with a grinding amount of 0.10~0.15, and the honing worm (designed by yourself) corresponding to the number of strokes can be used for high-speed honing on the lathe (as shown in the figure). The gear accuracy can reach level 7 or higher, the surface roughness can be reduced to Ra0.4 or more, and the gear meshing noise can be reduced to less than 70d.

The use of high-speed honing technology improves the surface roughness and meshing quality of the gear, and reduces the noise of the product's meshing transmission. EP imported equipment processing, perfect quality management, for gear surface roughness, if you have more questions or related processing needs, you can consult our technology free of charge.

Ever-Power Group

Ever-Power Group

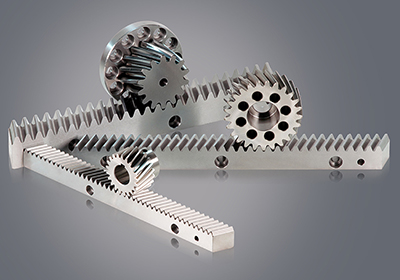

![Oil pump gear [customized]](ptogearboxes/xiaoE/upload/file/img/2020/10/5f9a8130d4e57.jpg)

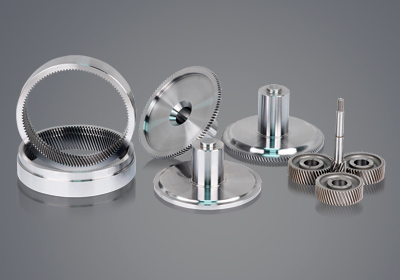

![Encoder gear [customized]](ptogearboxes/xiaoE/upload/file/img/2020/10/5f9a7c8ae4b27.jpg)