Manufacturing process description of parking gear of automobile reducer

Publication time: 2020-04-06 Website: https://ptogearboxes.com Edit: EP

The manufacturing and processing technology of the parking gear of the automobile reducer is as follows, for reference and understanding. For unclear parts or related gear processing requirements, you can consult EP for free.

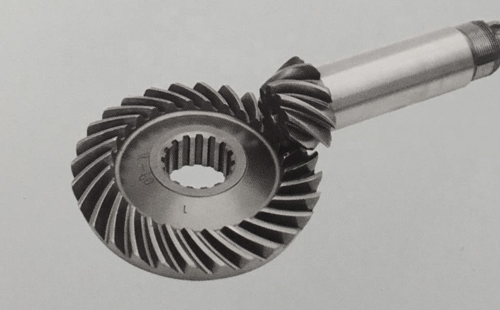

Parking gear of automobile reducer:

It includes a circular plate body. The circular plate body is provided with a central hole 1, an outer tooth surface 2 is provided on the outer side, and an inner tooth surface 3 is provided on the inner side. The external tooth surface is formed, and then the internal tooth surface is formed by the method of gear shaping.

Manufacturing process of parking gear of automobile reducer:

The hollow cylindrical shaft is first cold-extruded to form the bottom, and then the outer tooth surface and the inner tooth surface of the hollow cylindrical shaft are cold-forged and extruded, and finally several new energy automobile reducer parking gears are cut into the manufacturing process technology route Reasonable, the metal flow is not cut off, the product tooth surface strength is high, raw materials are saved, and the production efficiency is high.

The manufacturing process includes the following steps:

1. Cutting: Intercept the required metal bars;

2、球化退火:将坯料送入退火炉中加热至720℃—780℃作球化退火处理,球化率≥90%,表面硬度≤80HRC;

3. Billet shot blasting lubrication: remove surface defects, sandblasting, lubrication treatment;

4. Remove the bottom after cold forging and extrusion: send the lubricated billet into the reverse extrusion die, cold forging to form a hollow and blind cylindrical structure billet with a bottom, and then press to remove the bottom to form a hollow pass Hole cylindrical structure blank;

5. Annealing: heat the blank with the bottom removed to 680℃—720℃ for annealing treatment;

6. Billet making and lubrication: removal of surface defects and lubrication treatment;

7. Cold forging and extruding the inner and outer tooth surfaces: send the lubricated blanks into the cold forging and extrusion die, and cold forging and extruding the outer and inner tooth surfaces at one time;

8. Cutting: Cut the blank after cold forging and extruding the outer tooth surface and the inner tooth surface into several parking gears;

9. Heat treatment and cleaning and oiling: heat treatment, cleaning and anti-rust treatment of the cut parking gear.

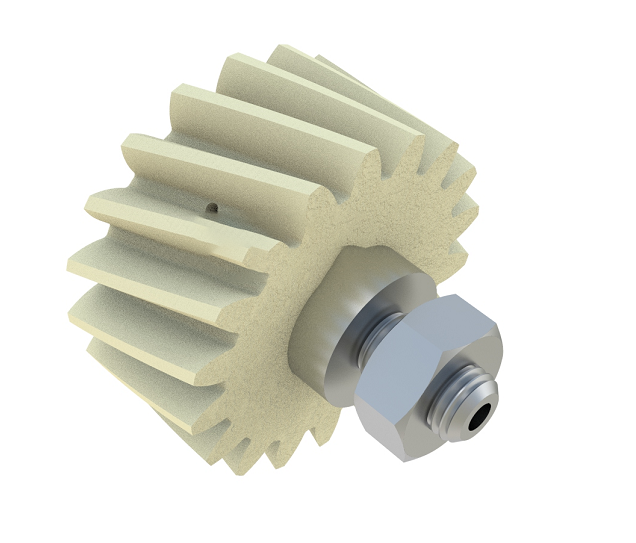

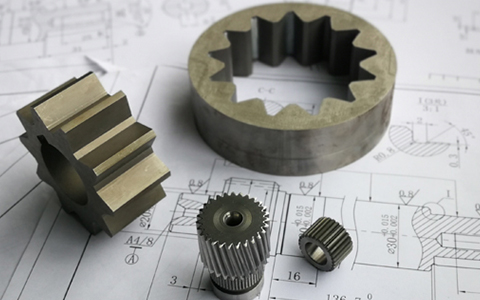

The above description includes but not limited to, welcome to add if there are any deficiencies. Ever-Power is a professionalPrecision gear machiningCustomized, high-precision, high-speed, high-speed, stable transmission, and widely used in reducers, gearboxes, robots and other mechanical equipment.

Ever-Power Group

Ever-Power Group

![Oil pump gear [customized]](ptogearboxes/xiaoE/upload/file/img/2020/10/5f9a8130d4e57.jpg)

![Encoder gear [customized]](ptogearboxes/xiaoE/upload/file/img/2020/10/5f9a7c8ae4b27.jpg)