Several common gear tooth profile processing methods

Publication time: 2020-05-08 Website: https://ptogearboxes.com Edit: EP

The descriptions of several common gear tooth profile processing methods are as follows, for reference and understanding. For unclear parts or related requirements, you can consult EP free of charge.

1. Machining method of gear tooth profile with accuracy above level 5

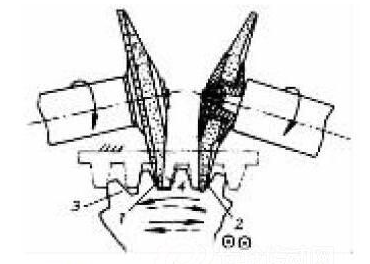

Coarse gear hobbing-fine gear hobbing-tooth end machining-quenching-calibration standard-rough grinding gear-fine grinding gear.

Gear grinding is currently the most accurate machining method in tooth profile machining, with the smallest surface roughness value, and the highest precision can reach 3-4.

2, 6-7 precision gear tooth profile processing method

Hardened gears can be used:

Rough hobbing-fine hobbing-tooth end processing-fine shaving-surface hardening-correction reference-honing.

3. Machining method of gear tooth profile below level 8 accuracy

a. The hardened and tempered gear can meet the requirements with gear hobbing or gear shaping.

b. Hardened gears can be used:

Rolling (shaping) tooth-tooth end processing-quenching-correction hole processing program.

However, the machining accuracy of the tooth profile should be improved by one level before quenching.

The choice of tooth profile machining plan mainly depends on the gear's accuracy grade, structure shape, production type and production conditions.

Tooth profile processing is the wholeGear processingCore.There are many processes in gear processing, all of which serve for tooth profile processing, and the purpose is to obtain gears that meet the accuracy requirements in the end.

The above description of gear tooth profile processing method is for reference only, and will not be notified if there is any update.

Ever-Power Group

Ever-Power Group

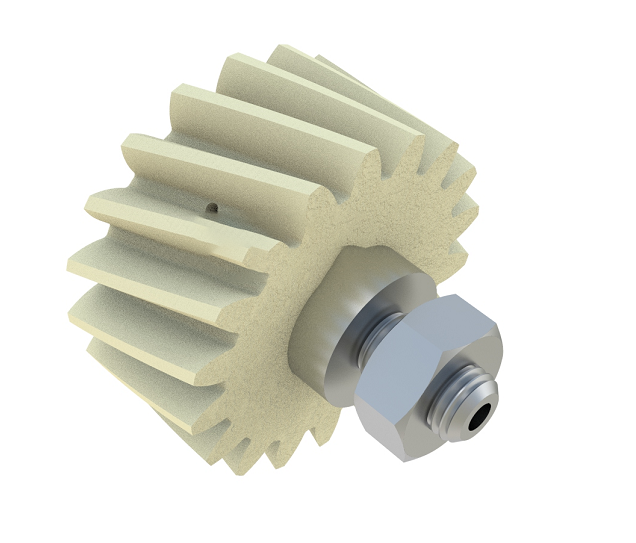

![Oil pump gear [customized]](ptogearboxes/xiaoE/upload/file/img/2020/10/5f9a8130d4e57.jpg)

![Encoder gear [customized]](ptogearboxes/xiaoE/upload/file/img/2020/10/5f9a7c8ae4b27.jpg)