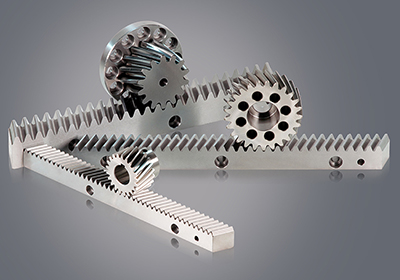

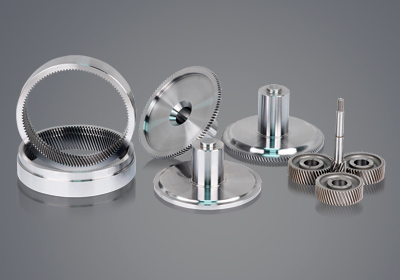

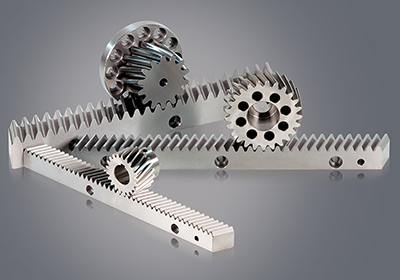

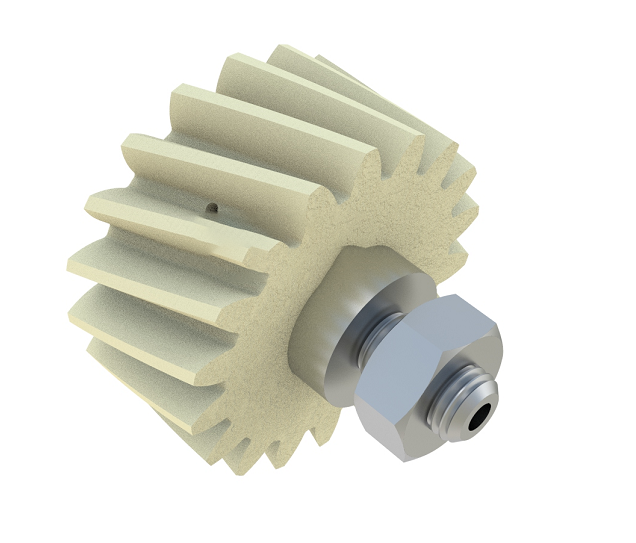

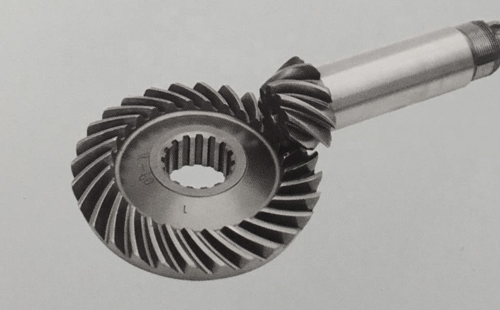

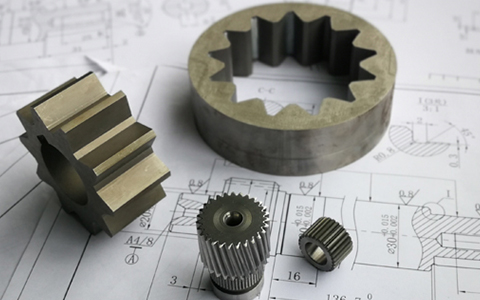

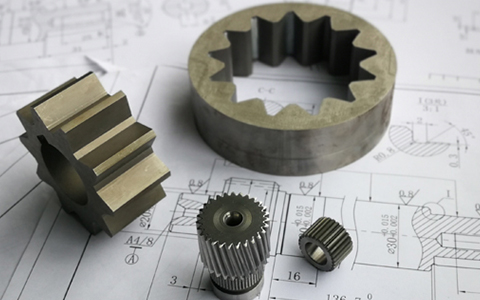

Technical requirements for processing and application of precision ground helical gears in reducers

Publication time: 2020-04-06 Website: https://ptogearboxes.com Edit: EP

The technical requirements for processing and application of precision ground helical gears in reducers are as follows, for reference, related questions orGear processingIf you need, you can consult EP for free.

Technical requirements for processing and application of precision ground helical gears in reducers:

1. Gear material: 20CrMnTi alloy steel, etc.

2. Gear processing accuracy: precision grinding and grinding, 5-6 grade accuracy.

3. Heat treatment: tempering, carburizing, quenching, etc.

4. Gear surface hardness: HRC58°-62°.

5. Gear core hardness: HRC33-40.

6. Smooth transmission, large carrying capacity, high efficiency, low vibration, low noise, low maintenance, long service life, etc.

7. In order to improve the load-carrying capacity of the gear, it is necessary to start trimming the tooth profile and helix.

Reducer gearIt is a key part that constitutes a mechanical product, and its quality is related to the level of the entire product.

For more technical issues related to precision ground helical gears for reducers, you can directly seek help from EP technology. Our technology can choose a suitable gear transmission solution according to your actual product performance requirements!

<Previous article:Some factors affecting the price of gear processing

Ever-Power Group

Ever-Power Group

![Oil pump gear [customized]](ptogearboxes/xiaoE/upload/file/img/2020/10/5f9a8130d4e57.jpg)

![Encoder gear [customized]](ptogearboxes/xiaoE/upload/file/img/2020/10/5f9a7c8ae4b27.jpg)