PTO Gearbox

EP

Tractor PTO Gearbox

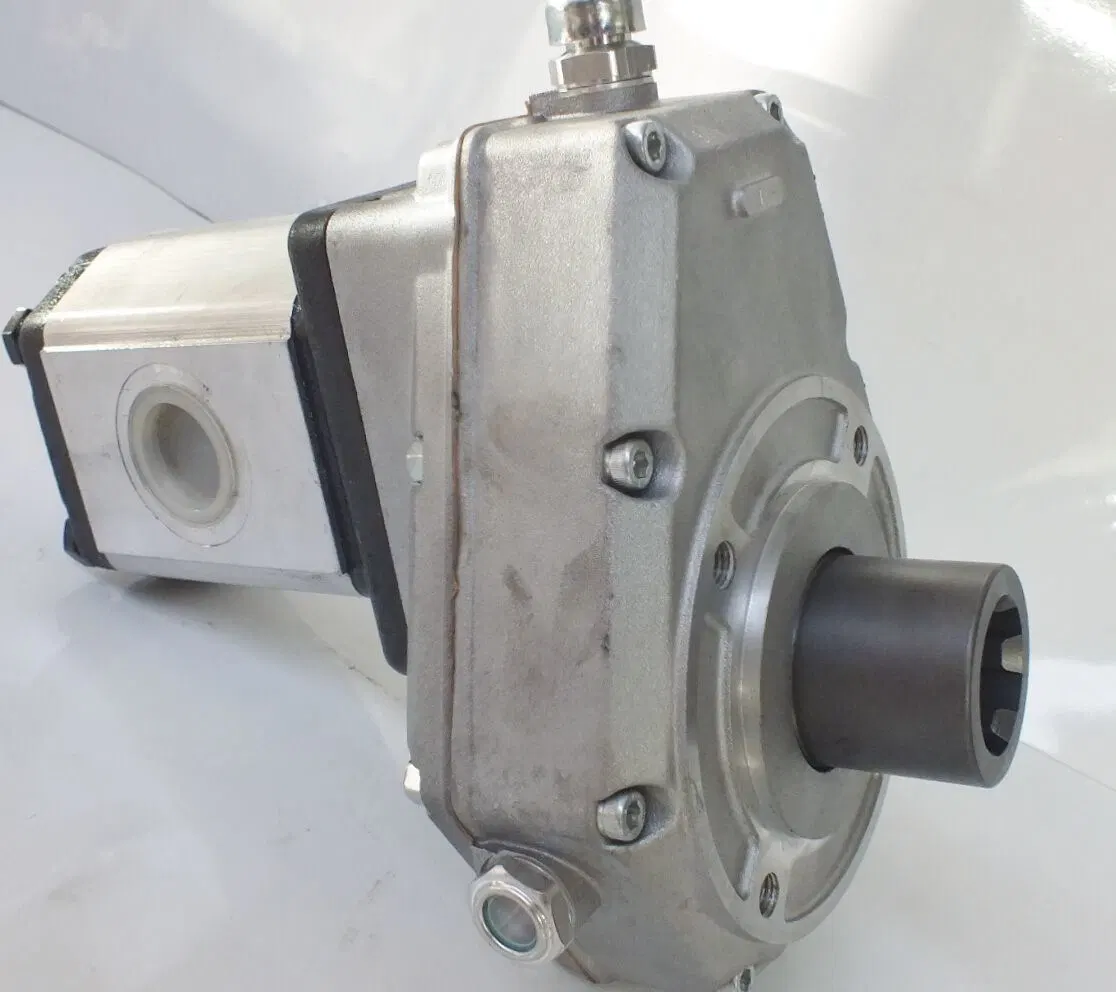

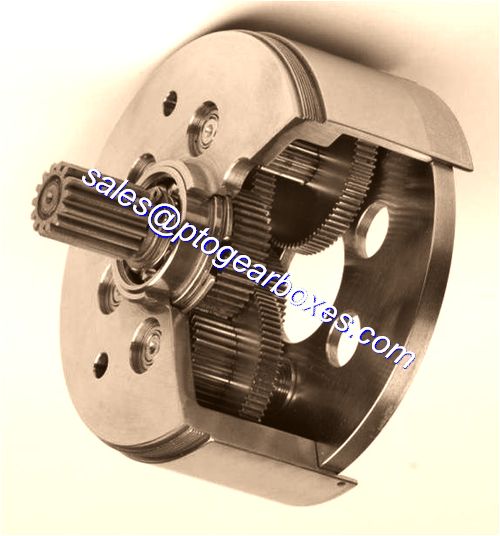

The PTO transmission is used to transfer power from the tractor engine to the auxiliary equipment on the vehicle. Typical applications include vacuum pumps, pump drives and hydraulic motors. It is important to select the proper gearbox for the application.

Typically, a PTO has a transmission ratio of two or three. This allows for a wider range of torque and speed. However, PTOs with two or three gears are more common than those with more gears.

The internal gearing of the PTO has a significant effect on the output speed. For example, a gearbox that provides a 3:1 gear ratio will increase the speed of the pto gearbox shaft by approximately 80%. In comparison, a gearbox with a 10:1 gear ratio will reduce the speed of the PTO shaft by approximately 65%.

Split shaft PTO transmissions are a good choice if you want to divert engine power to another output shaft. This type of gearbox is operated by separate clutches. If the engine stops running completely, the PTO cannot be operated.

Rich experience

Advanced technology

Professional services

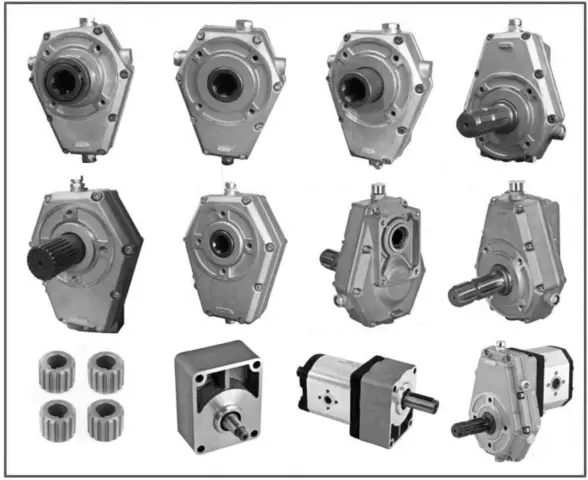

Agricultural PTO Gearbox

PTO gearboxes are key components of agricultural machinery. It is a device that increases the tractor’s speed by transmitting the hydraulic system’s power to the equipment being driven. These gearboxes come in a variety of sizes and applications.

Agricultural gearboxes are commonly used for harvesting, threshing and sowing. They are also used in manure pumps, spreaders and grain augers.

When shopping for an agricultural gearbox, it is important to find a gearbox whose features match your needs and budget. You should also make sure it’s made of high-quality materials. This will ensure that it is durable and you will be able to enjoy its performance for many years.

The most common material used to manufacture agricultural gearboxes is aluminum. Aluminum is a good choice because it is durable and resistant to corrosion. Another common material is zinc. Stainless steel is another popular choice.

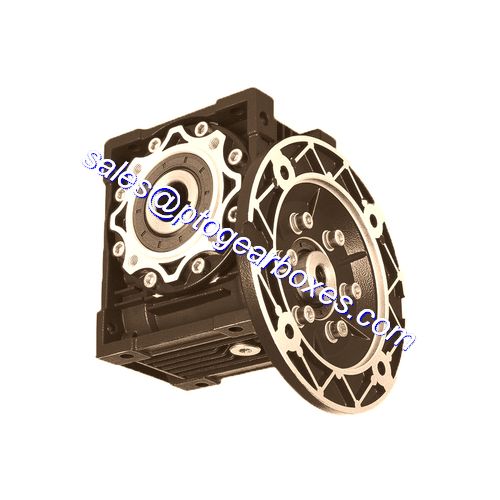

PTO gearbox

We are offering agricultural gearbox.

Shafted mounted gearbox for conveyer systems, mounting dimension are interchageable with fener

low noise and high output

smr shafted mounted gearbox for conveyer systems

1) all gears are heat treated and fixed to achieve low noise and high output

2) mounting dimensions are interchangeable with fener, sumimoto.

PTO Gearbox for Sale

As PTO gearbox manufacturers, we will do our best to provide you with the best quality service. If you need customized products, or the products you need are not found on our website, or need a product catalog, don’t worry; more of our products are still being uploaded. You can email us directly, and we will reply to you within 24 hours!

Advantages of PTO Gearbox

Versatility: PTO gearboxes provide a versatile power transfer solution, allowing the engine’s power to be utilized for various applications. They can transmit power to different types of equipment, such as pumps, generators, compressors, agricultural machinery, and industrial equipment.

Increased Efficiency: PTO gearboxes enable direct power transfer from the engine, eliminating the need for separate engines or motors for auxiliary equipment. This reduces energy losses, improves overall system efficiency, and optimizes fuel consumption.

Cost Savings: By using a single engine to power multiple devices through a PTO gearbox, significant cost savings can be achieved. This eliminates the need for separate engines or motors for each individual equipment, reducing upfront costs, maintenance expenses, and fuel consumption.

Compact Design: PTO gearboxes are usually compact in size and can be easily integrated into existing systems or vehicles. Their small footprint allows for efficient use of space and facilitates installation in tight or limited spaces.

Customization Options: PTO gearboxes are available in various configurations, allowing for customization based on specific application requirements. They can be designed with different gear ratios, output speeds, and torque capacities to match the specific needs of the equipment being powered.

Applications of PTO Gearbox

Agriculture: PTO gearboxes are extensively used in agricultural machinery, such as tractors, harvesters, and balers. They power equipment like mowers, tillers, sprayers, and feed mixers, enabling efficient operation of various farming tasks.

Construction and Industrial: PTO gearboxes find applications in construction equipment, such as excavators, cranes, and loaders. They are also used in industrial machinery like pumps, compressors, conveyors, and winches, where they provide reliable power transmission.

Commercial Vehicles: PTO gearboxes are commonly employed in commercial vehicles, such as trucks and buses. They power auxiliary equipment like hydraulic systems, refrigeration units, and power generators, enhancing the functionality and versatility of these vehicles.

Marine: PTO gearboxes are utilized in marine applications, powering equipment such as winches, anchors, and thrusters on boats and ships. They ensure efficient power transmission in marine environments.

Emergency Services: PTO gearboxes are used in emergency service vehicles, such as fire trucks and ambulances, to drive auxiliary equipment like hydraulic pumps, generators, and water pumps. This enables rapid deployment and operation of critical emergency systems.

Possible problems and solutions during the use of PTO gearbox

Noise and Vibration:

Problem: Excessive noise and vibration from the PTO gearbox can indicate misalignment, worn-out components, or improper lubrication.

Solution: Inspect and correct any misalignment of the gearbox and ensure that all components are in good condition. Check and replenish the lubricant as per the manufacturer’s recommendations.

Slippage:

Problem: Slippage occurs when the PTO gearbox fails to transmit power efficiently, resulting in reduced performance of the connected equipment.

Solution: Check the tension of the PTO belt or shaft coupling and adjust it as per the manufacturer’s guidelines. Ensure that the belt is properly aligned and replace it if it is worn out or damaged. If using a shaft coupling, verify that it is securely fastened and aligned with the driven equipment.

Overheating:

Problem: Overheating of the PTO gearbox can lead to premature wear, decreased efficiency, and potential damage to the gearbox.

Solution: Check for proper lubrication and ensure that the gearbox has the correct amount of lubricant. Verify that the lubricant is suitable for the operating conditions and replace it if necessary. Inspect for obstructions or restrictions in the cooling system and ensure proper ventilation around the gearbox.

Leakage:

Problem: Leakage of lubricant or hydraulic fluid from the PTO gearbox can occur due to damaged seals, gaskets, or worn-out components.

Solution: Inspect the gearbox for any signs of leakage and identify the source. Replace damaged seals or gaskets and repair or replace any worn-out components as needed. Ensure that the fluid levels are maintained within the recommended range.

PTO Engagement Issues:

Problem: Difficulty in engaging or disengaging the PTO can be caused by mechanical or electrical faults, such as a malfunctioning clutch, faulty control switch, or wiring issues.

Solution: Inspect the clutch mechanism and associated components for any damage or wear. Test the electrical connections and switches to ensure they are functioning correctly. Repair or replace any faulty components and ensure proper adjustment of the engagement mechanism.

Excessive Load or Overloading:

Problem: Applying an excessive load or overloading the PTO gearbox can result in overheating, premature wear, or even failure of the gearbox.

Solution: Verify the maximum load capacity of the PTO gearbox and ensure that the equipment being driven does not exceed this limit. If necessary, upgrade to a gearbox with a higher load capacity. Monitor the load on the gearbox during operation and avoid overloading.

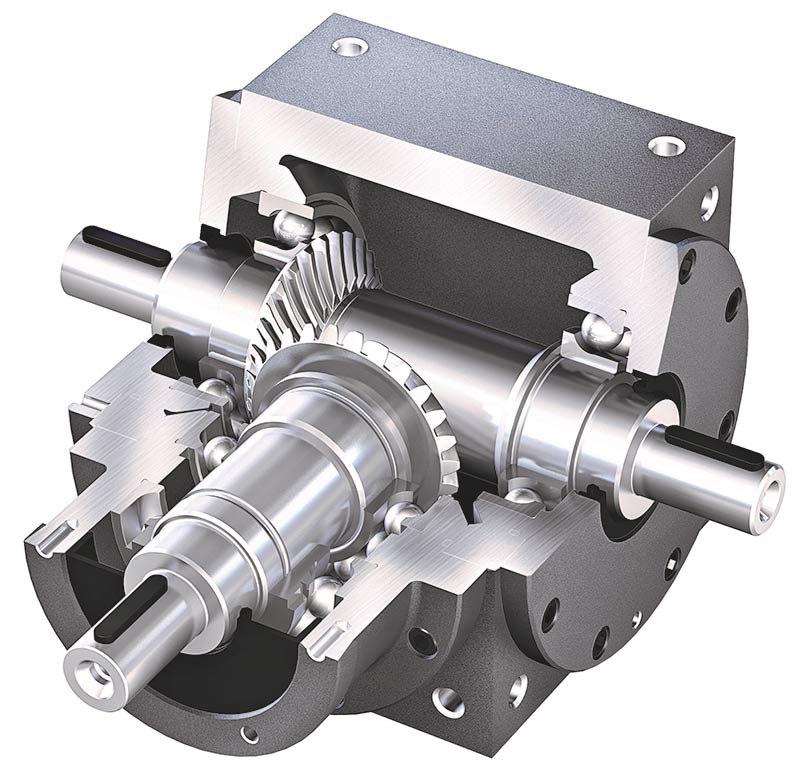

The PTO (Power Take-Off) shaft and PTO gearbox are two interconnected components that work together to transfer power from the engine to auxiliary equipment or machinery. Here’s an explanation of their relationship:

The PTO shaft is a rotating shaft that extends from the engine or transmission of a vehicle or machinery. It is designed to transmit power from the engine to the PTO gearbox. The PTO shaft usually has a splined or keyed end that connects to the input shaft of the PTO gearbox.

The PTO gearbox, on the other hand, is a mechanical device that is mounted on the vehicle or machinery. Its primary function is to receive rotational power from the PTO shaft and provide a power output to drive auxiliary equipment or machinery. The PTO gearbox contains a set of gears and other components that transfer and adjust the power output based on the specific requirements of the driven equipment.

The connection between the PTO shaft and PTO gearbox is typically achieved through a driveline coupling. This coupling ensures a secure and efficient transfer of power between the rotating PTO shaft and the input shaft of the gearbox. It allows the rotational motion and torque generated by the engine to be transmitted to the gearbox, which then adjusts the output speed and torque to match the requirements of the equipment being driven.

In summary, the PTO shaft serves as the input source of rotational power, transmitting it to the PTO gearbox. The PTO gearbox, with its gears and components, manipulates and adjusts the power output to drive auxiliary equipment efficiently. Together, they form a crucial power transmission system that enables the utilization of engine power for various applications.

How to select the right pto gearbox?

1. Power Requirements: Determine the power requirements of the equipment or machinery that will be driven by the PTO gearbox. Consider the required input power (from the engine) and the desired output power (for the driven equipment). Ensure that the PTO gearbox has a power rating that can handle the expected load and torque.

2. Speed and Gear Ratios: Assess the desired speed and gear ratios needed for the application. The PTO gearbox should be capable of providing the required output speed and torque based on the equipment’s specifications. Consider the available gear ratios and select a gearbox that can achieve the desired speed and torque conversion.

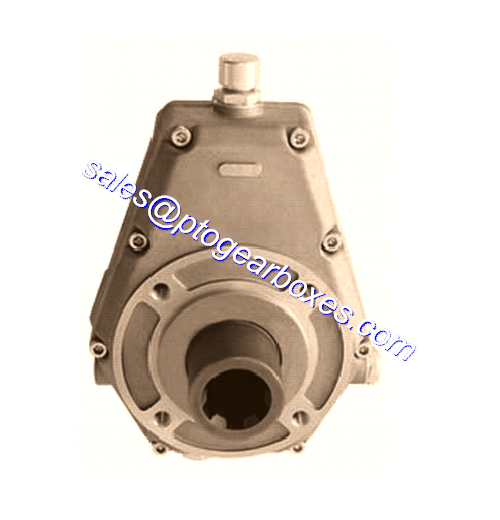

3. Shaft Type and Size: Determine the type and size of the PTO shaft that will be connected to the gearbox. PTO shafts come in various sizes and configurations (e.g., splined or keyed), so ensure that the gearbox has compatible input shaft specifications that match the PTO shaft.

4. Mounting and Compatibility: Consider the mounting requirements and compatibility with the vehicle or machinery. Assess the available space for installing the PTO gearbox and ensure that it can be properly mounted and aligned with the engine and driven equipment. Check for compatibility with the vehicle’s transmission or driveline system.

5. PTO Control Mechanism: Evaluate the control mechanism required for the PTO gearbox. Determine whether a mechanical, hydraulic, or electrical control system is needed based on the application and connectivity options available on the vehicle or machinery. Ensure that the control mechanism is compatible with the PTO gearbox.

6. Quality and Reliability: Choose a reputable and reliable manufacturer or supplier for the PTO gearbox. Consider the quality of materials, construction, and overall durability. Look for product warranties and customer reviews to ensure a reliable and long-lasting gearbox.

7. Consult Manufacturer Guidelines: Refer to the manufacturer’s guidelines and specifications for the specific machinery or vehicle. The manufacturer may provide recommendations or requirements for selecting the appropriate PTO gearbox based on the intended application.

pto

pto

gearbox

gearbox

Agricultural PTO Gearbox Suppliers

Agricultural PTO gearbox suppliers offer a wide range of products. These products are designed to keep your agricultural machinery efficient, reliable, and easy to operate. They help keep your tractor at the proper speed and help reduce downtime. Choosing a high-quality agricultural PTO transmission can also save you money.

It is important to choose products that can handle the harsh conditions of agricultural equipment. A high-quality agricultural gearbox will last for many years and is easy to repair or replace.

When selecting an agricultural gearbox, the following factors should be considered: smooth surface finish, high quality bearings, lubrication and load carrying capacity. Additionally, agricultural gearboxes should meet all safety and regulatory requirements.

For example, a high-quality right-angle gearbox should have a 76-degree surface finish and a 2.44:1 reduction ratio. This is the ideal finish for any machine.

Also, your gearbox should have an easily accessible design. Closed-loop seals keep out dust and debris, helping to reduce maintenance costs.

When to Change the Oil in a Gearbox

If you have a transmission, you may be wondering when to change the oil in it. It depends on the gearbox, its location and the oil used in it. You can also check for leaks.

First, you need to check the oil level. The water level should be less than halfway down the bottom shaft. Usually, higher levels will flood a bearing.

You should also check the backlash of the gears. Proper backflushing will allow the PTO to function properly. This can be determined by the depth of the grid.

You can also fill the equipment with pto gearbox oil. Usually, the power take-off installed on the engine or gearbox uses the oil of the main engine part. However, if your unit has a differential, you will need to add a small amount of gear oil.

If you’re not sure what a PTO is, look in the box. The PTO box is used to increase the drive speed of a tractor or other vehicle by transmitting power from the tractor’s PTO gearbox. They come in different sizes and some are able to work continuously.

Our Cooperation Start Here!