Gear shaft processing technology and application instructions

Publication time: 2020-04-01 Website: https://ptogearboxes.com Edit: EP

The gear shaft processing technology and application instructions are as follows, for reference and understanding. For related technical questions, please directly seek help from EP technicians.

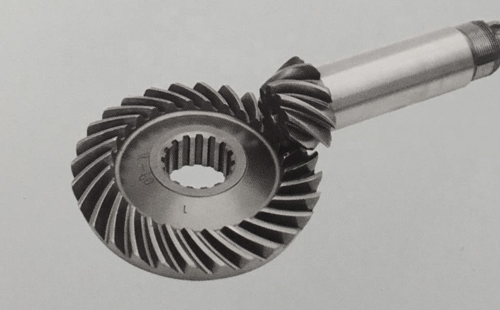

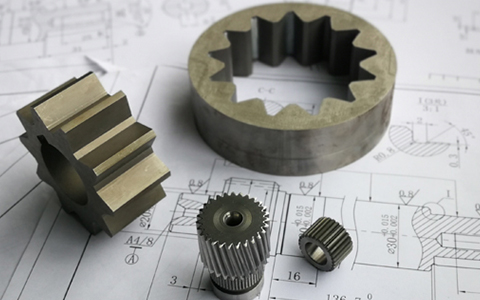

Gear shaftIt is generally in the shape of a metal round rod, and each segment can have different diameters.The complete machine for rotating parts in the machinery is mounted on the shaft, which refers to the complete machine that supports the migration and transformation of the complete machine and rotates with it to transmit motion, torque or bending moment.

XNUMX. Gear shaft processing technology:

The following process requirements are for low-carbon steel materials such as 20CrMnTi, 20Cr2Ni4, etc. As usual, you can use 45 without carburizing and quenching.About 300 under temperinggear.

Casting-Normalizing-Punching the center hole (the length may be more than 300, if it is short, the rough turning can be turned at both ends)-Rough turning-Flaw detection-Modulation-Fine turning-Gear hobbing-Clamping-Carburizing-Repairing the middle hole- Car carbon layer (spline standard requires low hardness and good toughness)-quenching (gear standard requires high hardness, impact load, and short life)-sandblasting-spline milling-clamp repair-training middle hole-rounded cross section- Gear grinding-clamp repair-inspection-flaw detection.

1. Unloading.

2. Rough car.

3. Quenching and tempering treatment (further improve the toughness of the gear shaft and the rigidity of the shaft).

4. Finish turning the tooth blank to size.

5. If there is a keyway on the shaft, the keyway can be processed first.

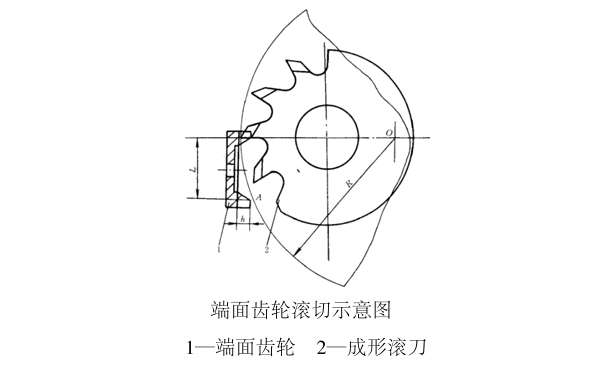

6. Gear hobbing.

7. Intermediate frequency quenching of the tooth surface (high-frequency quenching for pinion gears), the detailed hardness value of the quenching hardness needs to be determined according to the working conditions, load and other factors.

8. Grind teeth.

9. Product inspection.

XNUMX. Gear shaft application:

1. The gear shaft is the shaft and gear as a whole. However, when planning, try to shorten the length of the shaft.

2. Generally used in high-speed level (that is, low-torque level).

3. Generally small gears (with less teeth).

4. Generally, it is rarely used as a sliding gear for variable speed, and is generally a fixed-running gear.

The above gear shaft processing technology and application instructions, including but not limited to, welcome to add if there are any deficiencies.

Ever-Power Group

Ever-Power Group

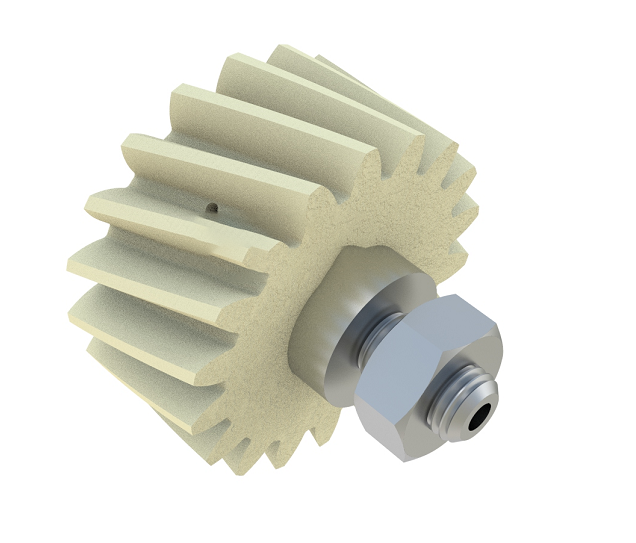

![Oil pump gear [customized]](ptogearboxes/xiaoE/upload/file/img/2020/10/5f9a8130d4e57.jpg)

![Encoder gear [customized]](ptogearboxes/xiaoE/upload/file/img/2020/10/5f9a7c8ae4b27.jpg)