Gear processing: description of shaft heat treatment conditions and material requirements

Publication time: 2020-04-02 Website: https://ptogearboxes.com Edit: EP

Gear processing: The working conditions and material requirements of shaft heat treatment are as follows, for reference.

1. Conditions: υ cycle ≥ 2m/S, small shaft under large bending load and friction conditions, such as small shaft of machine tool gearbox.Requirements: 15, 20, 20Cr, 20MnVB carburizing, quenching, low temperature tempering, HRC58-62.

2. Conditions: working in rolling or sliding bearings, light or medium load speed is slightly higher. ρU≤150N.m/(cm^2.s), high precision requirements, low impact and fatigue load.Requirements: 45 normalizing or quenching and tempering, HB228-255, surface quenching of journal or assembly parts, HRC45-50.

3. Conditions: working in sliding or rolling bearings, medium load, high speed, low core strength requirements, low precision, low impact, but high fatigue stress, such as grinders, heavy-dutygearSpindles such as milling machines.Requirements: 20Cr carburizing, quenching, low temperature tempering, HRC58-62.

4. Conditions: working in sliding bearings, υ circumference <2m/S, requiring small shafts and mandrels with higher hardness on the surface.Such as machine tool feed box, gearbox small shaft.Requirements: 45, 50, 40Cr, 42MnVB. Quenched and tempered for shafts with complex shapes, HB228-255, high frequency quenching at the journal, HRC45-50.

5、条件:水泵轴,要求足够抗扭强度和防腐蚀。要求:3Cr13及4Cr13 1000-1050℃油液,硬度分别为HRC42及HRC48。

6. Conditions: High-load spline shafts require high strength, wear resistance, and small deformation.Requirements: 45 high frequency heating, water cooling, low temperature tempering, HRC52-58.

7. Conditions: Rotating in sliding bearings, heavy load, high speed, high precision ≤0.003m, high fatigue stress, such as high-precision grinding machine boring machine spindle.Requirements: 38CrA1MoA quenching and tempering hardness HB248-286: journal nitriding, hardness Hv≥900.

8. Conditions: Yuejin-130 load-bearing (2.5 tons) automobile half-axle can bear impact, repeated bending fatigue and torsion, and the main load is overloaded and twisted. It requires adequate bending, torsion, and fatigue resistance. Good toughness.Requirements: 40r 35cr 42CrMo 40CrMnMo 40Cr quenched and tempered with intermediate frequency table quenching, surface hardness RC>52, depth 4-6mm, static torque 6900N.m, fatigue ≥30 times, estimated life ≥30km, metallographic structure: Soxhlet Body + Troostite (the original use of quenching and tempering plus high-frequency quenching life is only 4 km).

9. Conditions: working in sliding bearings, υ circumference<3m/S, requiring high hardness and small deformation, such as the small shaft of the intermediate belt transmission.Requirements: 40Cr, 42MnVB quenching and tempering, HB228-255, high-frequency quenching of journal, HRC45-50.

10. Conditions: C616-416 lathe spindle, 45# steel 1) bear alternating bending stress, torsion stress, and sometimes impact load. 2) The inner taper hole and the taper of the large end of the spindle are round, and there is often relative friction with the chuck and thimble. 3)Spline部分经常磕碰或相对滑动。4)在滚动轴承中动转,中速,中载。要求:1)整体调质后硬度HB200-230,金相组织为索氏体。2)内锥孔和外圆锥面处硬度HRC45-50,表面3-5m风金相组织为屈氏体和少量回火马氏体。3)花键部分硬度HRC48-53,金相组织同上。

11. Conditions: working in rolling or sliding bearings, light or medium load, low speed, low precision, slight impact, spindle with negligible fatigue load, or working in rolling bearings, light load, υ<1m/s The secondary spline shaft.Requirements: 45 quenching and tempering, HB225-255 (such as general simple machine tool spindle).

12、条件:电动机轴,主要受扭。要求:35及45正火或正火并回火,HB187及HB217。

13. Conditions: working in sliding bearings, medium or heavy load, high speed pu≤400N.m/cm^2.S, high precision, low impact and fatigue load.Requirements: 40Cr quenching and tempering, HB228-255 or HB248-286, surface quenching of journal, HRC≥54, surface quenching of assembly part HRC≥45.

14. Conditions: Others are the same as above, but the speed and accuracy requirements are higher than the above example, such as the grinding wheel spindle of a grinder.Requirements: 45Cr, 42CrMo and others are the same as above, and the surface hardness is HC>≥56.

15. Conditions: working in sliding or rolling bearings, heavy load, high-speed (pU≤400N.m/cm^2.s) impact, and high fatigue stress.Requirements: 18CrMnTi, 20Mn2B, 20CrMnMoVA carburizing and quenching, low temperature tempering, HRC≥59.

For more instructions on shaft heat treatment, please ask EP Technology for help.

<Previous article:Gear shaft processing technology and application instructions

Ever-Power Group

Ever-Power Group

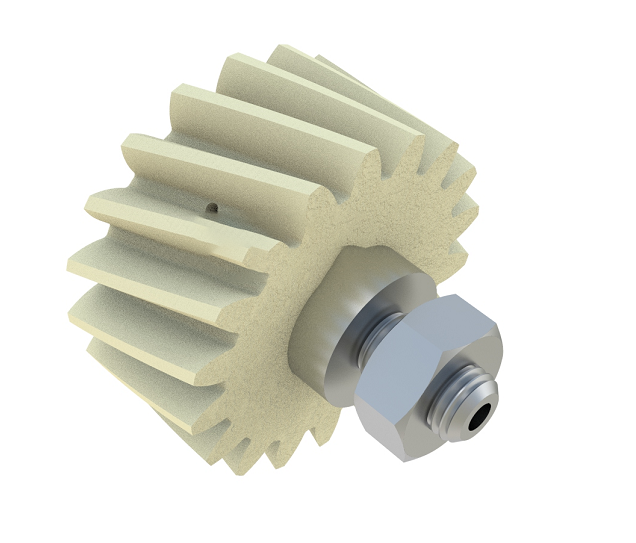

![Oil pump gear [customized]](ptogearboxes/xiaoE/upload/file/img/2020/10/5f9a8130d4e57.jpg)

![Encoder gear [customized]](ptogearboxes/xiaoE/upload/file/img/2020/10/5f9a7c8ae4b27.jpg)