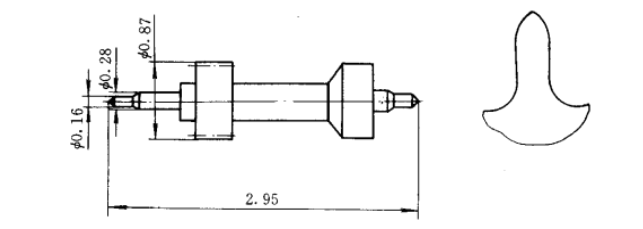

Milling process of small modulus gear shaft (for reference)

Publication time: 2020-05-22 Website: https://ptogearboxes.com Edit: EP

The milling process of small modulus gear shafts is described below for reference. For unclear parts or related requirements, you can consult EP free of charge.

Process 1: Cutting

Material designation: T10Pb polished bar stock.

Process 2: Car forming

The margin of the formed journal of the automatic car is 0.008mm, and the margin of the tooth top is 0.6mm.

Process 3: Copper plating

To prepare for chemical deburring.

Process 4: Milling teeth

gearThe outer diameter is 0.012mm, and the root diameter is up to the size.

Process 5: cleaning and deburring

Remove oil stains and deburring.

Process 6: Heat treatment

Quench and temper, protect with vacuum or gas.

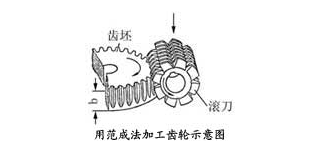

Process 7: Hobbing and polishing gear

Tooth surface roughness Ra0.08μm, tooth outer diameter to size.

Process 8: Grinding the journal

Surface roughness Ra0.04μm.

Process 9: Anti-oil diffusion or electroplating

Meet the anti-rust requirements.

Process 10: general inspection

Check whether the process requirements are met.

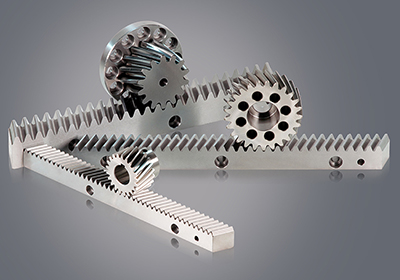

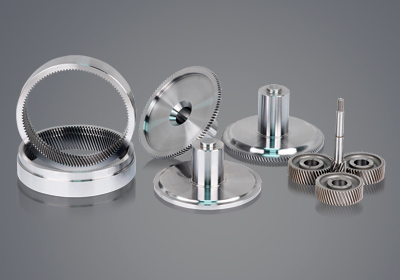

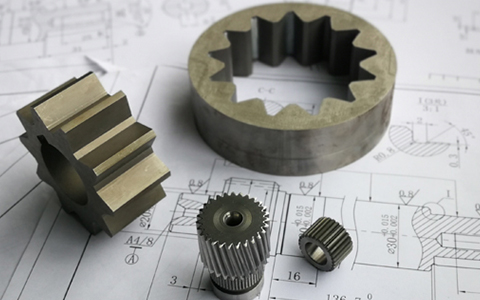

Gear milling process is suitable for machiningInvolute gearAnd square cycloidal gears, other non-involute gears can also be processed.Especially for some special gears that cannot be machined by the hobbing method, the gear milling method is widely used.

The above is the sharing of the relevant content of the milling process of the small module gear shaft, including but not limited to, welcome to add if there are any deficiencies.

Ever-Power Group

Ever-Power Group

![Oil pump gear [customized]](ptogearboxes/xiaoE/upload/file/img/2020/10/5f9a8130d4e57.jpg)

![Encoder gear [customized]](ptogearboxes/xiaoE/upload/file/img/2020/10/5f9a7c8ae4b27.jpg)