Application of Nitrided Steel in Internal Gears of Mining Machines and Other Products

Publication time: 2020-06-02 Website: https://ptogearboxes.com Edit: EP

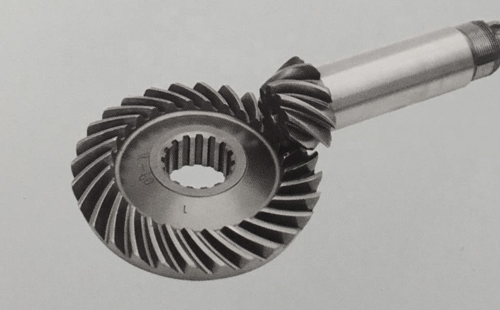

Nitrided steel is generally used for closed gearbox gears that transmit medium power and have certain impact load conditions.

Before nitriding, it must be quenched and tempered to provide a harder substrate before nitriding, which can give full play to the characteristics and comprehensive mechanical properties of the nitrided layer, and improve thegearThe deformation has a significant effect, and the hardness of the nitride layer is generally up to (Equivalent to HRC70), obviously has higher wear resistance than carburized and quenched steel.

(Equivalent to HRC70), obviously has higher wear resistance than carburized and quenched steel.

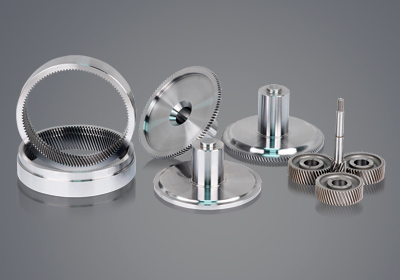

This type of steel is mainly used for manufacturing on mining machines in underground coal minesInternal gearAnd gears with low speed and heavy load.

The fatigue strength of the nitrided gear is 25%-30% higher than that of the hardened gear. The temperature during nitriding is only 510-560℃, and there is basically no deformation after nitriding. It is often used in the last process of gear manufacturing.

The disadvantage is that when the nitriding depth exceeds 0.6mm, the nitriding time is long, and the nitrided layer is brittle after nitriding.The use of glow ion nitriding can improve its brittle hardness after nitriding. , So the brittleness has also been improved.

, So the brittleness has also been improved.

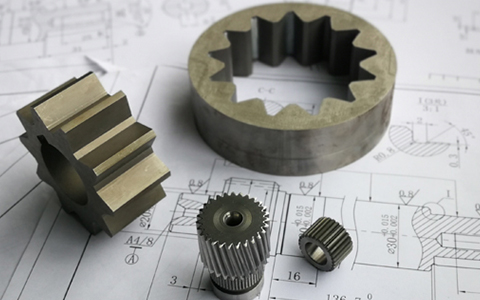

The hardness requirements of the specific nitrided steel vary by steel grade. Commonly used traditional nitrided steels are 38CrMnA1, 42CrMo, 35CrMo, 30CrMnsi, 35CrMnsi, 35CrMnV, and 40CrMnMo.

Among them, the allowable contact stress of 38CrMnAl is 1100MPa and the allowable bending stress is 375NPa. For other medium carbon alloy structural steels, the allowable contact stress is ≥1000MPa, and the allowable bending stress is about 425MPa.

Ever-Power Group

Ever-Power Group

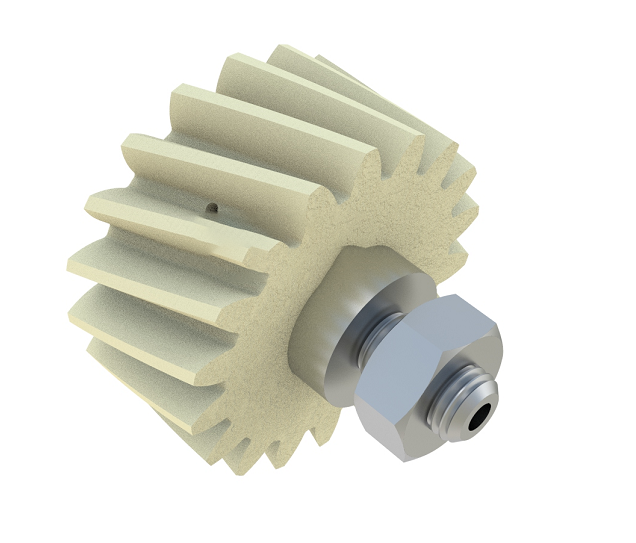

![Oil pump gear [customized]](ptogearboxes/xiaoE/upload/file/img/2020/10/5f9a8130d4e57.jpg)

![Encoder gear [customized]](ptogearboxes/xiaoE/upload/file/img/2020/10/5f9a7c8ae4b27.jpg)