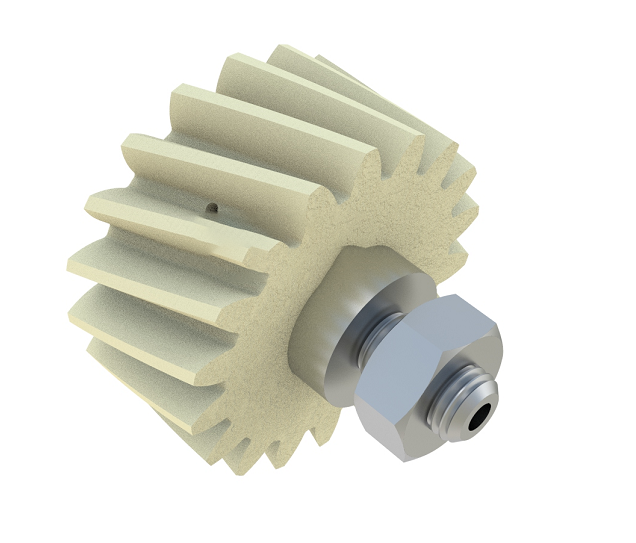

Application of quenched and tempered steel and surface hardened steel in reduction gears of mine hoisting winches, open-pit mining machinery, etc.

Publication time: 2020-06-02 Website: https://ptogearboxes.com Edit: EP

Quenched and tempered and surface hardened steel:

It is mainly used for closed gearboxes with large transmission power and medium-load transmission. The tooth surface contact stress is 500-1100MPa, and it has high static strength, impact toughness and high fatigue strength.

This type of steel is medium-carbon alloy steel, generally after quenching and tempering, the teeth are cut and tempered with a hardness of HB240-280, and then subjected to salt bath overall quenching or induction heating surface quenching. It is HRC2-3 higher than general quenching, and has fatigue strength and impact resistance. The toughness is improved, and the quenching deformation is also small, because it generally does not grind the teeth, and the manufacturing accuracy is 7~8. The quenching depth of the induction heating table depends on the frequency of the induction coil (high frequency, intermediate frequency or power frequency), and its surface hardness HRC45-56.

The allowable contact stress during design is generally 1200 MPa, and the allowable bending stress is 370 MPa.Mainly used for mine hoisting winches, open-pit mining machinery, Yijin mining machinery, etc.Reducer gear.

The commonly used steel grades for gearbox gears of mine hoisting winches, surface mining machinery, metallurgical mining machinery, etc. are:

40Cr, 35CrMo, 42CrMo, 40CrMnMo, 40CrNi and other quenched and tempered and surface hardened steels.

The latter four steels are all fine-grained color steels with high magical toughness, strong mechanical properties, fatigue resistance and hardenability.

Ever-Power Group

Ever-Power Group

![Oil pump gear [customized]](ptogearboxes/xiaoE/upload/file/img/2020/10/5f9a8130d4e57.jpg)

![Encoder gear [customized]](ptogearboxes/xiaoE/upload/file/img/2020/10/5f9a7c8ae4b27.jpg)