What are the noise and vibration levels associated with a PTO gearbox?

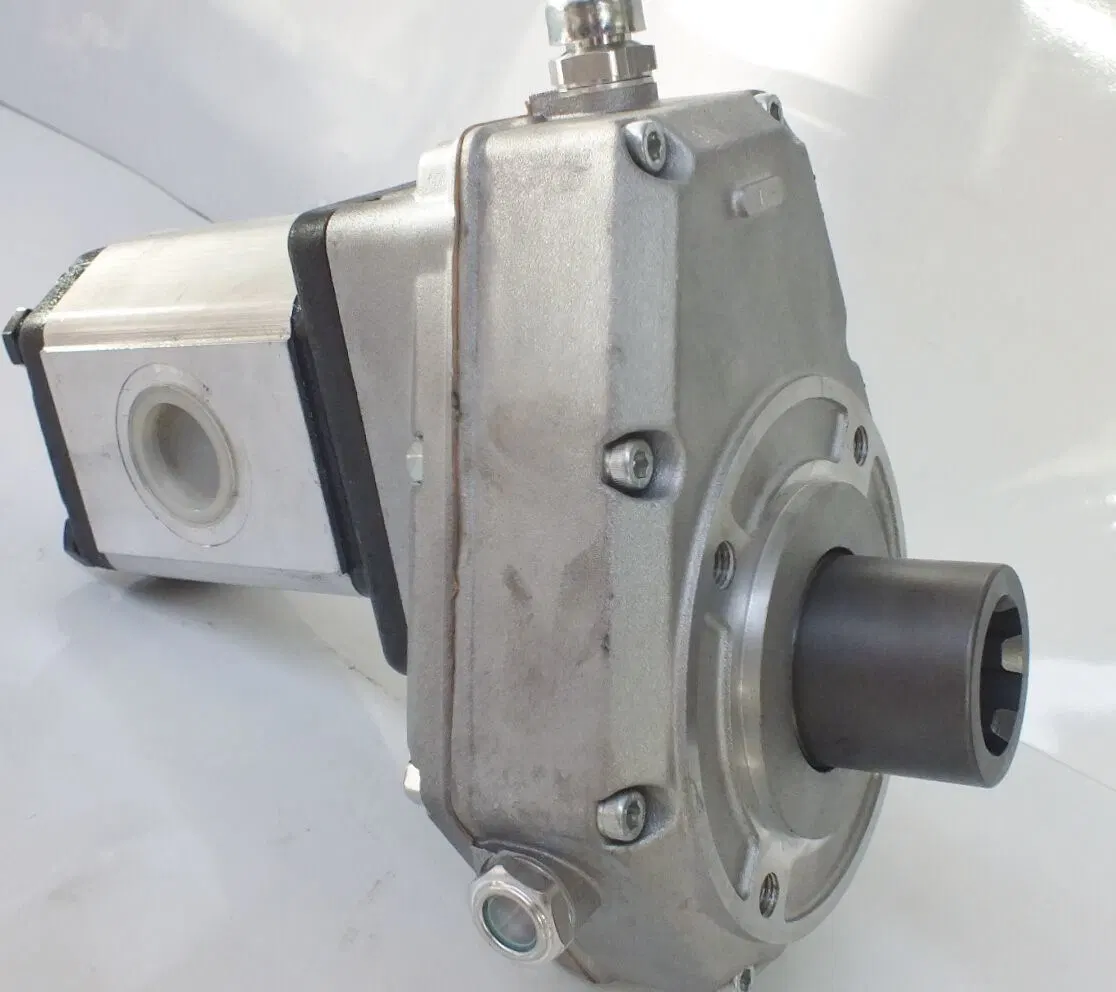

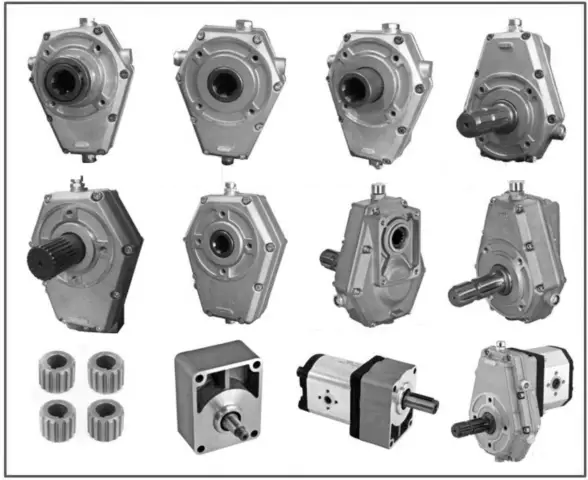

A Power Take-Off (PTO) gearbox is a mechanical device that transfers power from a vehicle’s engine to auxiliary equipment or machinery. It is typically mounted on the vehicle’s transmission or driveline and provides a rotational power output through a driveshaft.

The Advantages of Using a PTO Gearbox

- Versatility: PTO gearboxes offer a versatile power source that can be easily connected to different types of equipment or machinery, allowing for multiple applications without the need for separate power sources.

- Efficient Power Transmission: PTO gearboxes efficiently transfer power from the vehicle’s engine to the driven equipment, ensuring minimal power loss during transmission. This results in improved overall system efficiency.

- Increased Productivity: By utilizing a PTO gearbox, equipment and machinery can be operated without the need for an additional engine or power source. This increases productivity by reducing downtime and simplifying the power transmission process.

- Cost Savings: PTO gearboxes eliminate the need for standalone engines or motors for auxiliary equipment, resulting in cost savings in terms of equipment acquisition, maintenance, and fuel consumption.

- Controlled Power Output: PTO gearboxes often provide multiple gear ratios, allowing users to adjust the output speed and torque to suit specific applications. This control over power output enables efficient operation and optimal performance.

- Integrated System Design: PTO gearboxes are designed to integrate seamlessly with the vehicle’s transmission or driveline system, ensuring compatibility and ease of installation. This integration simplifies the overall system design and enhances reliability.

- Durability and Longevity: PTO gearboxes are engineered to withstand heavy loads and continuous operation. They are built with robust materials and undergo rigorous testing, ensuring durability and long service life even in demanding working conditions.

Applications of PTO Gearboxes

PTO gearboxes find extensive use in various fields, such as:

- Agricultural Machinery: Tractors, combines, balers, and mowers often employ PTO gearboxes to power agricultural implements like rotary cutters, hay balers, seeders, and sprayers.

- Construction Equipment: Excavators, loaders, backhoes, and cranes utilize PTO gearboxes to power attachments like hydraulic pumps, winches, augers, and concrete mixers.

- Trucks and Commercial Vehicles: PTO gearboxes are used in trucks and commercial vehicles to power auxiliary equipment such as hydraulic lifts, dump bodies, refrigeration units, and compressors.

- Industrial Machinery: Conveyor systems, pumps, mixers, and generators utilize PTO gearboxes to power material handling, fluid transfer, and power generation tasks.

- Emergency Vehicles: Fire trucks and ambulances use PTO gearboxes to power equipment such as hydraulic rescue tools, water pumps, and lighting systems.

- Marine Applications: PTO gearboxes are employed in marine vessels for powering auxiliary equipment such as winches, cranes, pumps, and propulsion systems.

- Forestry Equipment: Wood chippers, stump grinders, and log splitters use PTO gearboxes to provide power for processing and handling wood materials.

- Municipal and Public Works: Street sweepers, snowplows, and garbage trucks use PTO gearboxes to power various attachments and functions.

Working Principle of a PTO Gearbox

The working of a PTO gearbox involves the following steps:

- Power Input: The PTO gearbox receives power from the vehicle’s engine through the transmission or driveline system.

- Power Transmission: The PTO gearbox transfers the power to the output shaft through a series of gears and other components.

- Power Output: The output shaft provides rotational power to the driven equipment or machinery through a driveshaft or other connection method.

- Driven Equipment Operation: The driven equipment or machinery utilizes the power output from the PTO gearbox to perform the desired task or function.

Installation and Maintenance of PTO Gearboxes

Proper installation and maintenance of a PTO gearbox are crucial for optimal performance and longevity. The following steps can help ensure trouble-free operation:

- Installation: Follow the manufacturer’s instructions and guidelines carefully when installing a PTO gearbox.

- Lubrication: Regular lubrication is necessary for the smooth operation and longevity of a PTO gearbox. Ensure that the gearbox is adequately lubricated to minimize friction and wear.

- Inspection and Cleaning: Periodically inspect the PTO gearbox for any signs of damage, leaks, or excessive wear. Clean the gearbox and remove any debris or contaminants that may interfere with its operation.

- Alignment and Tension: Check the alignment of the PTO gearbox and ensure that it is properly aligned with the engine and driven equipment. Also, inspect any belts or driveshafts for proper tension and adjust as necessary to maintain optimal power transfer.

- Regular Maintenance: Follow the recommended maintenance schedule provided by the manufacturer. This may include tasks such as changing lubricants, inspecting and replacing worn components, and performing any necessary adjustments or repairs.

How to Choose a PTO Gearbox

Consider the following factors when selecting a PTO gearbox:

- Power Requirements: Consider the power requirements of the driven equipment and select a PTO gearbox that can handle the required torque and rotational speed.

- Compatibility: Ensure that the PTO gearbox is compatible with the vehicle’s transmission or driveline system. Consider factors such as input/output shaft sizes, mounting options, and connection methods.

- Gear Ratio and Speed Control: Evaluate the gear ratios available in the PTO gearbox and choose one that provides the desired output speed and torque for the intended application.

- Durability and Reliability: Look for a PTO gearbox that is built with durable materials and has a reputation for reliability. Consider factors such as load capacity, sealing mechanisms, and overall construction quality.

- Safety Features: Check if the PTO gearbox has safety features such as interlocks or guards to prevent accidental engagement or disengagement, ensuring operator safety.

- Easy Maintenance: Consider the accessibility of maintenance points and the availability of spare parts for the PTO gearbox. Choose a model that facilitates easy maintenance and has good manufacturer support.

- Budget and Cost Considerations: Evaluate the cost-effectiveness of the PTO gearbox while considering factors such as initial purchase price, maintenance costs, and potential long-term savings in terms of efficiency and durability.

Common Problems and Solutions

Some common problems that can occur with PTO gearboxes are:

- Noise and Vibration: Excessive noise and vibration can indicate misalignment, worn-out components, or improper lubrication. Inspect and correct any misalignment of the gearbox and ensure that all components are in good condition. Check and replenish the lubricant as per the manufacturer’s recommendations.

- Slippage: Slippage occurs when the PTO gearbox fails to transmit power efficiently, resulting in reduced performance of the connected equipment. Check the tension of the PTO belt or shaft coupling and adjust it as per the manufacturer’s guidelines.

- Overheating: Overheating can lead to premature wear, decreased efficiency, and potential damage to the gearbox. Check for proper lubrication, ensure that the gearbox has the correct amount of lubricant, and inspect for obstructions in the cooling system.

- Leakage: Leakage can occur due to damaged seals, gaskets, or worn-out components. Inspect the gearbox for any signs of leakage and replace damaged seals or gaskets.

- PTO Engagement Issues: Difficulty in engaging or disengaging the PTO can be caused by mechanical or electrical faults. Inspect the clutch mechanism and associated components, test the electrical connections and switches, and repair or replace any faulty components.

- Excessive Load or Overloading: Applying an excessive load or overloading the PTO gearbox can result in overheating, premature wear, or even failure of the gearbox. Verify the maximum load capacity of the PTO gearbox and avoid overloading.

The Importance of PTO Shafts

PTO shafts play a crucial role in transmitting power from the PTO gearbox to the driven equipment. They connect the two components and transfer the rotational power output from the gearbox to the equipment. At PTO Gearboxes, we offer a wide range of PTO shafts that are compatible with various PTO gearboxes and equipment. Our PTO shafts are built with high-quality materials and undergo rigorous testing to ensure durability and reliability.

In conclusion, PTO gearboxes are an efficient and versatile power source for various equipment and machinery. They offer several advantages such as controlled power output, increased productivity, and cost savings. However, proper installation, maintenance, and selection of a PTO gearbox are essential for optimal performance and longevity. At PTO Gearboxes, we provide high-quality PTO gearboxes and shafts that are built to last and meet your specific requirements.

In conclusion, PTO gearboxes are an efficient and versatile power source for various equipment and machinery. They offer several advantages such as controlled power output, increased productivity, and cost savings. However, proper installation, maintenance, and selection of a PTO gearbox are essential for optimal performance and longevity. At PTO Gearboxes, we provide high-quality PTO gearboxes and shafts that are built to last and meet your specific requirements.