Two kinds of gear cutting methods: Fan Cheng method and forming method related description

Publication time: 2020-06-15 Website: https://ptogearboxes.com Edit: EP

Two kinds of gear cutting methods: Fan Cheng method and forming method are described below respectively for reference.

According to the machining principle, the cutting of tooth profile can be divided into two types: generative method (fan method) and profiling method (forming method). It has the advantage of high machining accuracy and is currently the main method of tooth profile processing.

1. Development method (Fan Cheng method)

It is a method of cutting out the tooth profile by using the meshing movement of the gear cutter and the tooth blank.Different number of teethgear, As long as the modulus and the tooth profile angle are the same, they can be processed with the same tool.

The methods of machining tooth profile with the principle of generative (fancheng) include: shaving, honing and grinding, hobbing, shaping and other methods.Among them, shaving, honing and grinding belong to the tooth profile finishing methods.

The machining precision and productivity of Fancheng (Fancheng) are high, and the tool versatility is good, and it is widely used in production.

2. Profiling method (forming method)

The shape of the cutting edge of the tool used is the same as the shape of the groove of the gear to be cut. The method of machining the tooth profile by the profiling method includes: milling the teeth with a special shaped gear milling cutter or grinding the teeth with a shaped grinding wheel.

The profiling method has low machining accuracy due to indexing errors and tool installation errors; each tooth slot needs to be repeatedly retracted, indexed, cut in and cut out, which increases auxiliary man-hours and reduces production efficiency; no A special gear processing machine tool is required, and the gear milling cutter has a simple structure, low price, and low processing cost.

The profiling method of tooth milling is suitable for repairing and machining low-precision teeth below grade 9 in single-piece and small batch production.

In addition, drawing on the broaching machineInternal gearIt also belongs to the profiling method.Although this method has high productivity, it is necessary to manufacture expensive special broaches, which is only suitable for mass production of internal gears with small radial dimensions.

The above is the description of the two cutting methods of gears, including but not limited to, welcome to add if there are any deficiencies.

Ever-Power Group

Ever-Power Group

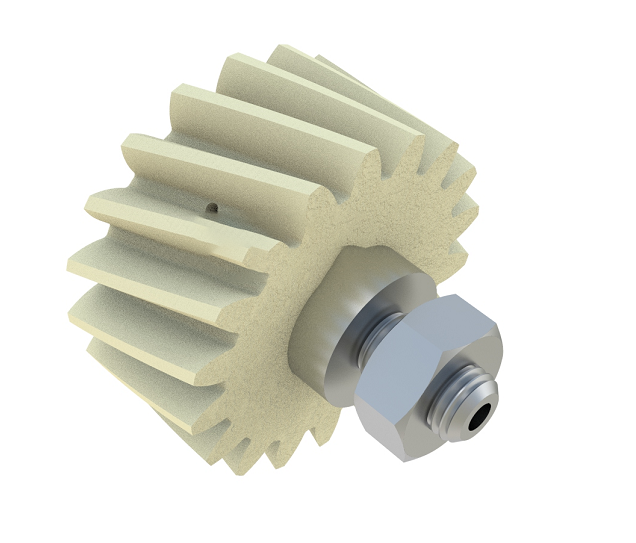

![Oil pump gear [customized]](ptogearboxes/xiaoE/upload/file/img/2020/10/5f9a8130d4e57.jpg)

![Encoder gear [customized]](ptogearboxes/xiaoE/upload/file/img/2020/10/5f9a7c8ae4b27.jpg)