Helical gear processing

Publication time: 2019-11-09 Website: https://ptogearboxes.com Edit: EP

Helical gear processingThe movement and transmission principle of time:

Differential motion transmission chain: to ensure that when the tool post moves a helical lead L along the axis of the workpiece, the workpiece makes an additional turn to form a helical tooth profile.Belongs to the internal link transmission chain.

Mounting angle of hob:

The installation angle δ of the hob when hobbing the helical cylindrical gear is:

δ=β±ω

When the spiral direction of the helical gear tooth to be processed is the same as that of the hob, it takes "one" sign, and when the spiral direction is different, it takes "+" sign.

The installation angle δ of the hob when hobbing the spur gear is:

δ=±ω

β—Gear helix angle

ω—screw angle of hob

Machining worm gear movement and transmission principle:

1. Radial feed method:

2. Tangential feed method:

For more helical gear processing content, please refer to EP Precision gear machining Free consultation.The above content includes but not limited to, welcome to add if there are any deficiencies.

Ever-Power Group

Ever-Power Group

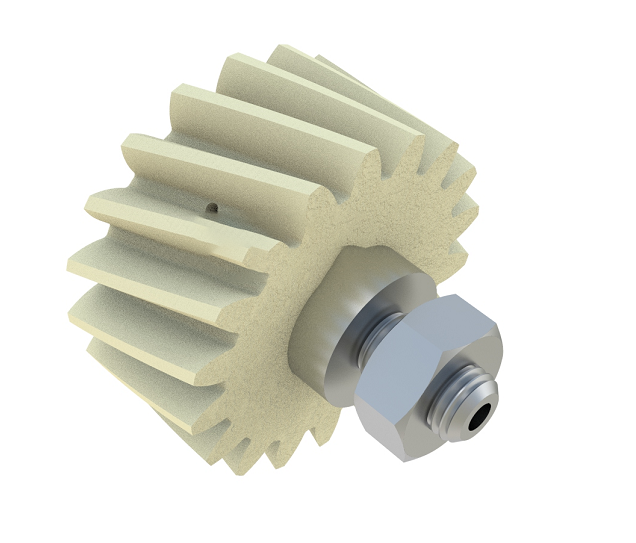

![Oil pump gear [customized]](ptogearboxes/xiaoE/upload/file/img/2020/10/5f9a8130d4e57.jpg)

![Encoder gear [customized]](ptogearboxes/xiaoE/upload/file/img/2020/10/5f9a7c8ae4b27.jpg)