Internal gear processing method

Publication time: 2020-04-20 Website: https://ptogearboxes.com Edit: EP

Internal gear processing methodThe instructions are as follows, for reference only. For technical questions, you can directly seek help from our technology.

XNUMX. A principle of internal gear processing:

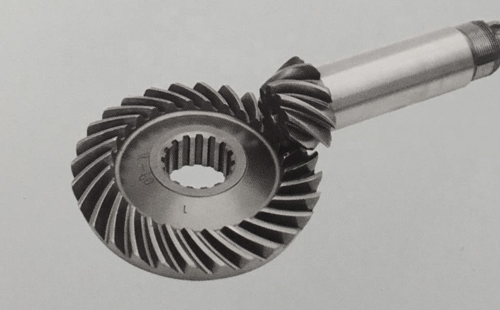

The processed gear blank and the gear turning tool (helical gear shaper tool) are mounted on two intersecting shafts, and the internal teeth are in a state of meshing.

Then, on the one hand, the two sides are forced to rotate, and on the other hand, the tool is fed along the axial direction of the tooth blank, so that the fan becomesgearCome.

The cutting force is the component force produced by the vertical (workpiece axis) component speed of the tool pitch circle peripheral speed, and is combined with the feed force of the machine tool in the vertical direction.

Internal gearThe machining of gear teeth is to use this kind of sliding to carry out the normal machining of gears.

3. Three characteristics of internal gear processing:

1. The efficiency is 2-4 times that of the gear shaping method.

2. There is no impact force, and the tool loss is small because there is no reciprocating cutting motion during cutting.

3. The tool cost is low, and it is easy to regrind and maintain.

The above internal gear processing methods include but are not limited to, if there are any deficiencies, welcome to add, if there is any update without notice!

Ever-Power Group

Ever-Power Group

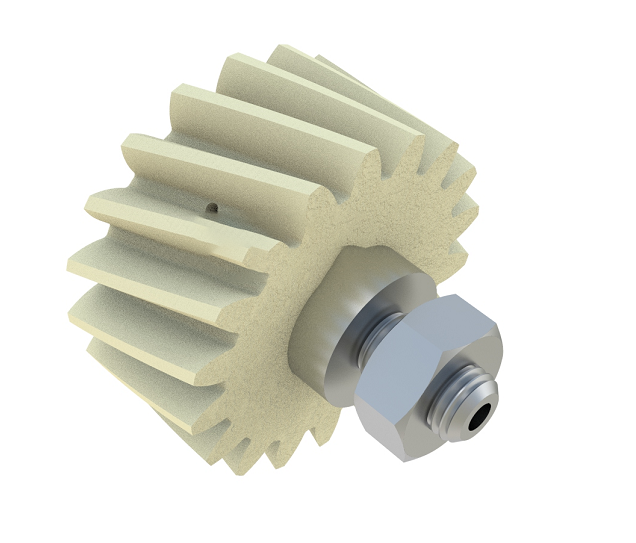

![Oil pump gear [customized]](ptogearboxes/xiaoE/upload/file/img/2020/10/5f9a8130d4e57.jpg)

![Encoder gear [customized]](ptogearboxes/xiaoE/upload/file/img/2020/10/5f9a7c8ae4b27.jpg)