Gear pump gear processing technology and related technical issues

Publication time: 2020-05-26 Website: https://ptogearboxes.com Edit: EP

Gear pump gearThe description of the processing technology and related technical issues are as follows, for reference and understanding.

Gear pump gear processing process:

Rough turning shape-fine turning gear shape-after turning it, send it to the inspection department, pass the inspection, and send it to the hobbing workshop-rough milling-fine milling-send to the inspection department for inspection-send to the hard department, quenching-the gear goes smoothly carry out.

Some technical problems in the processing of gear pump gears:

1. Tooth blank

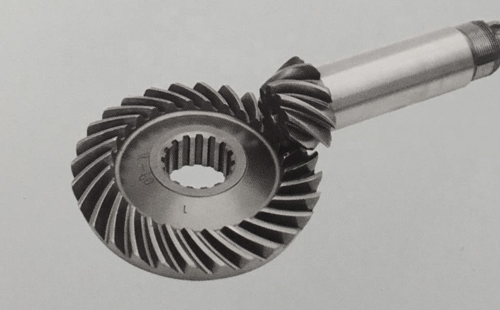

Medium and high pressure and high pressure gear pumpsgearAll gears are integral gears with connecting shafts. The gear blanks generally use die forgings. Due to the large machining allowance of forgings, both energy and materials are consumed.

At present, some factories use precision forgings, and choose bars whose thickness is the journal size plus the margin, and heat the middle part of the linden to the roughness of the gear. You can also use friction welded parts as tooth blanks, which saves energy and materials. Reduce the processing time.

2. Arc center hole

Since all the processing procedures of the gear pump are based on the center hole, the gear processing accuracy is required to be high.

Therefore, the contact between the center hole and the cone surface of the center is a ring-shaped belt contact, with good contact, accurate positioning, and easy grinding of the center hole.

3. The depth of the center hole and the distance between the two center holes

Generally, the production of gear pumps is mass production, and all the machining procedures of pump gears are based on two center holes as the machining benchmark.

In order to simplify the adjustment of the machine tool and make the processing operation convenient, the depth of the center hole of the gear to the end face of the journal and the distance between the two center holes should be strictly controlled, and special monitoring tools should be set up for inspection in the processing process.

The gears of the low-pressure gear pump bear small radial load and transmit torque. Generally, the gears and the transmission shaft are integrated, so that the processing technology is good.

The gears of medium and high pressure and high pressure gear pumps bear a large radial load and transmit torque, and the gears and the transmission shaft are made integral.

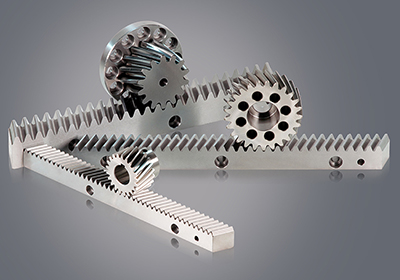

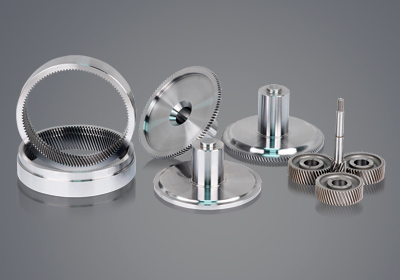

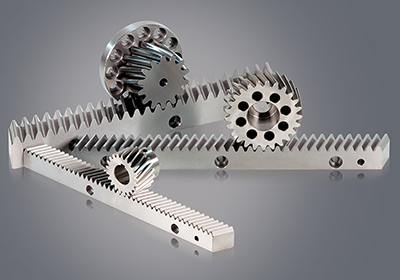

Ever-Power Group

Ever-Power Group

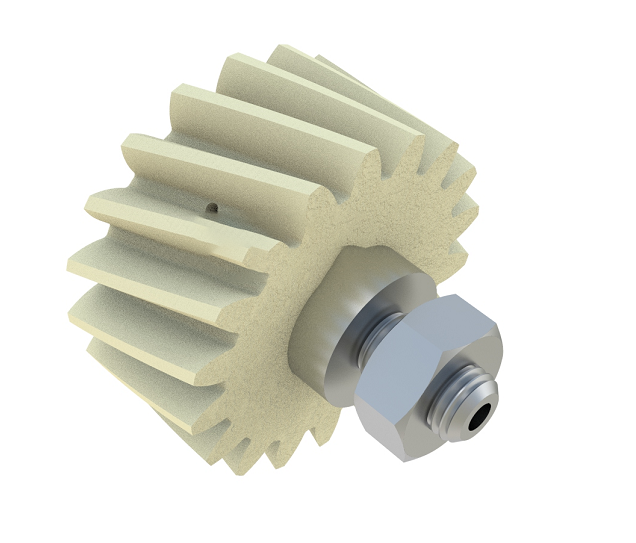

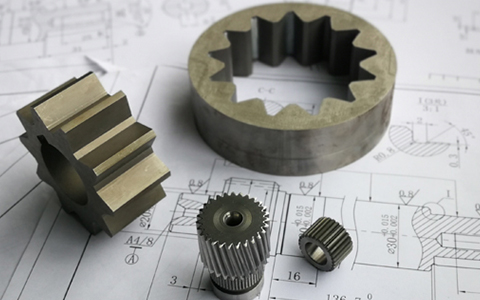

![Oil pump gear [customized]](ptogearboxes/xiaoE/upload/file/img/2020/10/5f9a8130d4e57.jpg)

![Encoder gear [customized]](ptogearboxes/xiaoE/upload/file/img/2020/10/5f9a7c8ae4b27.jpg)